Our Services

Comprehensive manufacturing and machining solutions designed to meet your unique industrial requirements with precision, quality, and reliability.

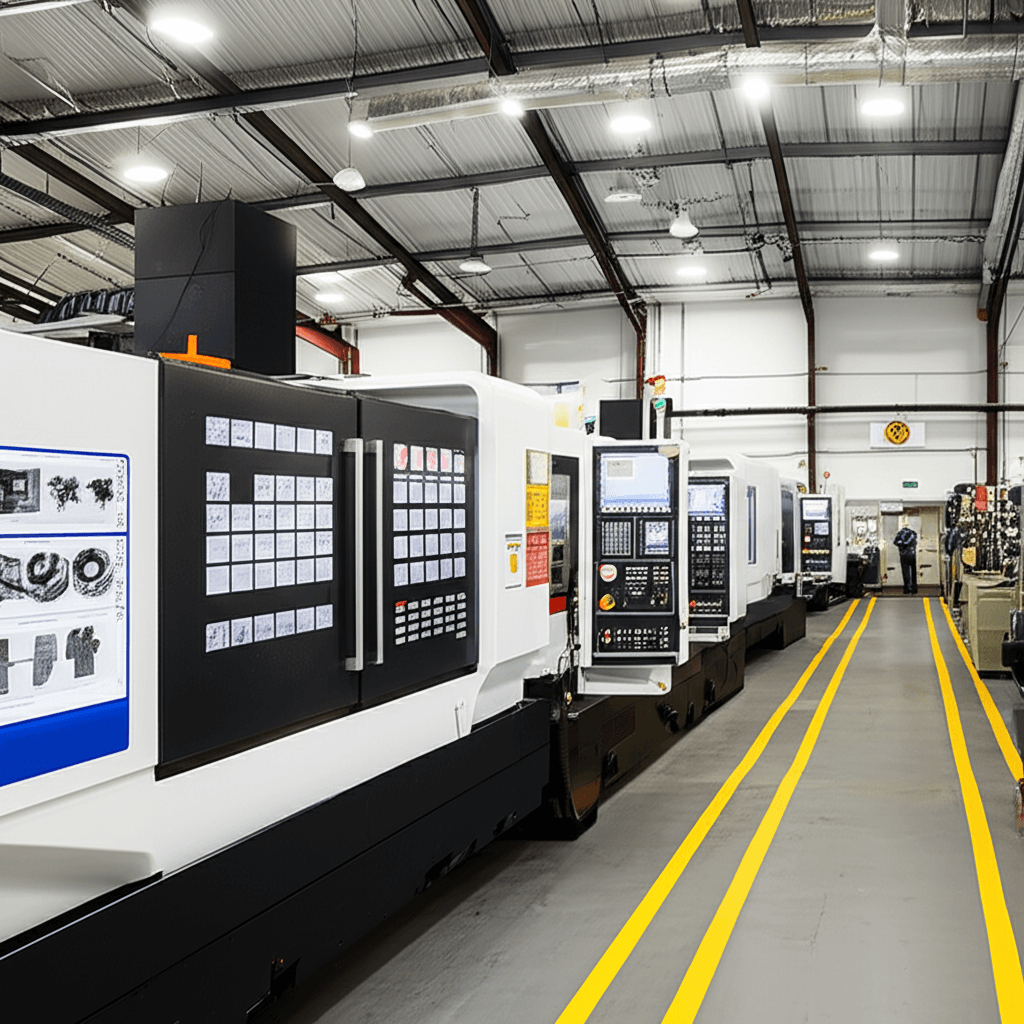

Manufacturing Excellence

From precision CNC machining to custom manufacturing solutions, we deliver quality results that exceed expectations.

Precision CNC machining for complex components with tight tolerances and superior surface finish.

Key Features:

- High Precision Machining (±0.005mm tolerance)

- Multi-Axis Capabilities (3, 4, and 5-axis)

- Advanced Quality Assurance Systems

- Fast Turnaround Times (24-48 hours)

- Material Expertise (Aluminum, Steel, Titanium)

- Surface Finish Excellence (Ra 0.8-3.2μm)

Applications:

Vertical Machining Center services for efficient and accurate production of various components.

Key Features:

- 3-Axis & 4-Axis VMC Operations

- High Speed Machining Capabilities

- Automated Tool Change Systems

- CAD/CAM Integration

- Rigid Tapping Capabilities

- Through-Spindle Coolant

Applications:

Specialized manufacturing of custom parts tailored to your specific requirements and specifications.

Key Features:

- Design Consultation Services

- Material Selection Expertise

- Prototype Development

- Quality Testing & Validation

- Reverse Engineering

- Design for Manufacturing (DFM)

Applications:

Large-scale production capabilities for high-volume manufacturing with consistent quality.

Key Features:

- High Volume Production Capacity

- Cost Optimization Strategies

- Statistical Quality Control

- Timely Delivery Schedules

- Inventory Management

- Supply Chain Integration

Applications:

Advanced 3D printing solutions for rapid prototyping and small-batch production.

Key Features:

- Multiple Material Options

- High Resolution Printing

- Rapid Prototyping Services

- Post-Processing Capabilities

- Color Printing Available

- Multi-Part Assembly

Applications:

Custom-engineered automated machines designed for specific manufacturing processes and applications.

Key Features:

- Custom Design & Engineering

- Automated Operation

- Process Integration

- Quality Control Systems

- Safety Compliance

- Remote Monitoring

Applications:

Why Choose Automecnica?

Our commitment to excellence, innovation, and customer satisfaction sets us apart in the manufacturing industry.

Quality Assurance

ISO certified quality management with rigorous testing protocols

Fast Turnaround

Rapid delivery without compromising on quality standards

Expert Team

Highly skilled engineers and technicians with decades of experience

Industry Leading

Cutting-edge technology and industry-best practices

Our Process

From initial consultation to final delivery, we follow a systematic approach to ensure exceptional results.

Consultation

We analyze your requirements and provide expert recommendations for optimal solutions.

Design & Planning

Our engineers create detailed designs and manufacturing plans tailored to your specifications.

Production

State-of-the-art manufacturing with continuous quality monitoring and testing.

Delivery & Support

Timely delivery with comprehensive after-sales support and maintenance services.

Ready to Start Your Project?

Get in touch with our experts today to discuss your manufacturing requirements and receive a custom quote tailored to your needs.